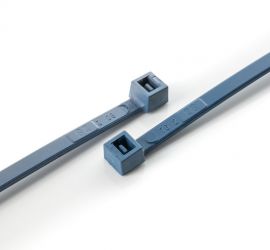

Detectable Cable Ties

Detectable cable ties are primarily used in environments where contamination in the production process must be quickly and accurately detected, such as in the food and chemical industries. Our range includes detectable cable ties made from two types of materials (polyamide and polypropylene), and from two brands: our own WKK brand and Ty-Rap®, a brand by ABB.

Types of detectable cable ties

In our assortment, you will find three types of detectable cable ties:

Properties of detectable cable ties

The key feature of detectable cable ties is that they can be easily detected during production processes. They are made from blue plastic mixed with metal pigments. The color blue is rarely found in natural food products, making it highly visible in the food industry. Furthermore, the metal pigments allow even small fragments of the cable tie to be detected using a metal detector.

Detectable cable ties nade from polyamide 6.6

Detectable cable ties are made from plastic blended with metal pigments, but different types use different plastics: polyamide 6.6 and polypropylene. We offer two types of detectable cable ties made from polyamide 6.6.

WKK plastic cable ties with metal pigments

Our in-house WKK brand detectable cable ties are made from polyamide 6.6 mixed with metal pigments. They can be used in temperatures ranging from -40 °C to +85 °C, and are halogen- and silicone-free. They comply with flammability class UL 94 HB.

These ties have a plastic locking tongue, which is the main difference compared to the Ty-Rap® version, which uses a stainless steel locking tongue.

Ty-Rap® plastic cable ties with metal pigments

The Ty-Rap® plastic cable ties with metal pigments are largely similar to the WKK version in terms of properties. They also withstand temperatures between -40 °C and +85 °C, and are halogen- and silicone-free. However, they differ from the WKK version in a few key aspects: they comply with flammability class UL 94 V-2 and they have a stainless steel (RVS) locking tongue, whereas the WKK version uses a plastic tongue.

Ty-Rap® detectable cable ties made from polypropylene

These cable ties also contain metal pigments, just like the polyamide 6.6 version, but are made from polypropylene, which offers better resistance to chemicals such as salts and acids than polyamide 6.6. Additionally, polypropylene floats, making these ties easier to detect in tanks containing chemicals.

They comply with UL 94 HB, are halogen- and silicone-free, and are suitable for use in temperatures between -40 °C and +85 °C. These also feature a plastic locking tongue.

Applications of detectable cable ties

Detectable cable ties are used in environments where contamination of the production process must be quickly, efficiently, and reliably detected. This includes industries such as chemical, pharmaceutical, and food production. In these industries, it is essential that if a cable tie or part of one ends up in the final product or production line, it can be detected either visually (thanks to the blue color) or by metal detection (due to the metal pigments).

Personal advice

Wondering which type of detectable cable tie is best suited to your application? Contact one of our advisors – they’ll be happy to help you find the right solution!