Cable ties per material quality

The material a cable tie is made of determines the conditions in which the cable tie can be used. For example, when a cable tie is exposed to temperatures above 100 °C, you will need heat-resistant cable ties made from polyamide 4.6 – regular cable ties are made from polyamide 6.6.

WKK offers cable ties made from 10 different types of materials:

Polyamide 6.6

Polyamide 6.6 is the most commonly used material for manufacturing cable ties. In most situations where cable ties are used, polyamide 6.6 is sufficient. It is both halogen-free and silicone-free and is resistant to temperatures up to +85 °C. Black cable ties made from polyamide 6.6 are UV resistant.

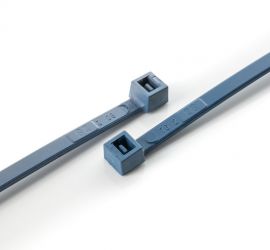

Polyamide 6.6 with metal pigments

Polyamide 6.6 with metal pigments has the same properties as 'regular' polyamide 6.6, with one important difference: tiny metal particles are mixed into the plastic. This allows even small pieces of the cable tie to be detected using a metal detector. This makes the material ideal for use in, for example, the food industry.

Polyamide 6.6 heat-resistant

This plastic also shares most of the same properties as polyamide 6.6, with the key difference being a higher heat resistance. This material can withstand temperatures up to 120 °C.

Polyamide 4.6 heat-resistant

Polyamide 4.6 is similar to polyamide 6.6 but has a slightly different molecular structure – indicated by the different numbers following "polyamide" (our range includes polyamide 4.6, 6.6, and 12).

Polyamide 4.6 can withstand higher temperatures than polyamide 6.6, namely up to a maximum of 150 °C.

Polyamide 12

Polyamide 12 is a more versatile plastic than polyamide 6.6. For example, it is more resistant to chemicals than polyamide 6.6. Additionally, it absorbs less moisture, making it less sensitive to environmental influences. This makes the material extremely suitable for outdoor use.

Polypropylene

Polypropylene is resistant to a wide range of chemicals, including salts, acids, and alcohol. Furthermore, polypropylene floats on liquids because it absorbs little moisture.

Polypropylene with metal pigments

This plastic shares the same properties as ‘regular’ polypropylene, but also contains microscopic metal pigments. As a result, even small pieces of this material can be detected with a metal detector. This makes it especially suitable for use in, for example, the pharmaceutical industry.

Ethylene tetrafluoroethylene (ETFE)

Ethylene tetrafluoroethylene is also known as Tefzel®. This material, developed by DuPont, is resistant to extreme conditions. It can withstand gamma radiation, chemicals, UV radiation, and radioactive radiation. Tefzel® is also resistant to temperatures up to +170 °C.

Stainless steel AISI 304

Stainless steel offers a long lifespan, making it suitable for use in harsh environments. The uncoated version can withstand temperatures of up to +538 °C. In addition, it has a high tensile strength and is, of course, non-flammable, halogen-free, and silicone-free.

Available in both coated and uncoated versions.

Stainless steel AISI 316L

Stainless steel of quality AISI 316L is resistant to harsh environmental conditions that can affect steel, including vibrations, weathering, corrosion, and radiation.

Available in both coated and uncoated versions.

Personal advice

Not sure which material is best suited for your application? Contact one of our advisors – they’ll be happy to help!